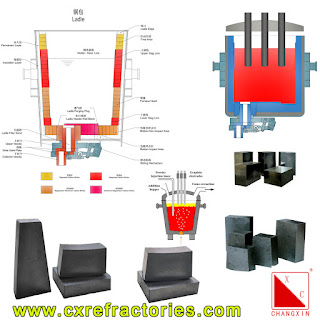

When MgO-C bricks are used for refining ladle furnaces and ladles, they are mainly used in headroom and slag lines. According to the operating conditions, the refractory materials used in these parts must have high temperature resistance, thermal shock resistance, and resistance to mechanical corrosion caused by slag erosion.

So in the past, these parts used magnesia-chromium refractory materials, but considering that chromium pollutes the environment, its consumption has been reduced, and now magnesia-carbon bricks are used.

Since the magnesia-carbon bricks in the new ladle will be severely damaged during the preheating process, the loose decarburized layer can reach 30-60mm thick. This layer is washed away during the injection of molten steel, bringing the magnesia grains into the slag.

Obviously, preventing the carbon in the magnesia carbon bricks from being burned out during preheating is one of the important steps to improve the service life of the magnesia carbon bricks at the ladle clearance and slag line.

Its technical measures, in addition to compounding the composite antioxidant into the magnesia carbon brick, the key is to cover the surface of the magnesia carbon brick with an alkali-containing low-melting glass phase liquid after lining, so as to protect the ladle magnesia carbon brick. Carbon is not burned off during the preheating process of the ladle.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality ladle magnesia carbon bricks are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Article Source:The use of aluminum-magnesium-carbon bricks on LRF

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:info@cxrefractories.com

Website:https://www.cxrefractories.com

没有评论:

发表评论